Description

Description

Light on Weight. Heavy on Performance.

Enhanced, innovative design with new optional features

The upgraded LDM Series features two new optional features to enhance performance and safety. First, a chain with a fixed rear bar has been added to increase efficiency while reducing material discharge from the rear, resulting in a safer working experience. Second, a custom-engineered pin mount is now available, perfectly suited to your carrier, ensuring seamless integration with your equipment.

Designed and manufactured in North America, the LDM Series mulcher attachment has been rigorously tested and approved on the rugged west coast, by the very people it was designed for. You can trust its durability and performance in the toughest conditions.

With the LDM Series, you have the flexibility to configure your hydraulic flow as low as 15 GPM @ 5000 PSI, making it adaptable to a wide range of applications. It can efficiently tackle brush and trees. Available in 30" and 50" large cut widths, and with a choice of three different cutter teeth to suit your working conditions, you can tailor it to your specific requirements.

The mulcher is driven by a variable-tension hydraulic bent-axis piston motor, paired with our Promac Automated Torque Control (ATC) for optimal efficiency and performance. Additionally, Promac uses high-strength steel and wear-resistant components that are easily replaceable, ensuring smooth operation for years to come.

Upgrade to the improved LDM Series mulcher attachment and experience enhanced performance, safety, and durability for your forestry operations. Trust Promac for top-quality equipment that meets your needs and exceeds your expectations.

Standard Features

- Wide use of high-strength, high-strength steel all over

- Standard variable torque of 55cc bent-axis piston motor the option of Promac ATC

- Sharpenable and rotatable"chipper" blades "chipper" teeth

- Dust seals with bolts aid in keeping debris from the machine's bearings

- Skids with a weld-in design composed out of 1/8" AR400 wear plates

- Anvil with a welded back made from AR400 plate

- Stub-shafts for rotors that can be changed with Spherical roller bearings

- Direct drive using isolation coupler. A proven, effective way to protect the motor of the mulcher drive.

- Chip production rotor (bite limiter)

- The options include an excavator mounted as well as the rear chain bar

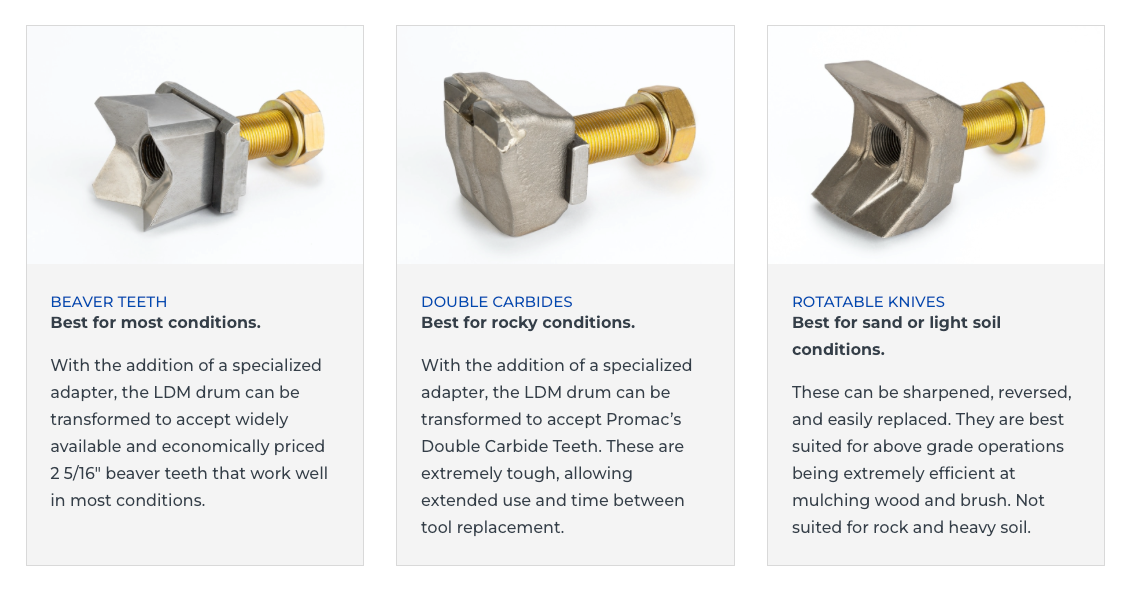

- Options for tooth configurations (adapters needed) Double carbide teeth, industry-standard beaver teeth

- Hoses and couplers are not included.

Standard Features at a Glance

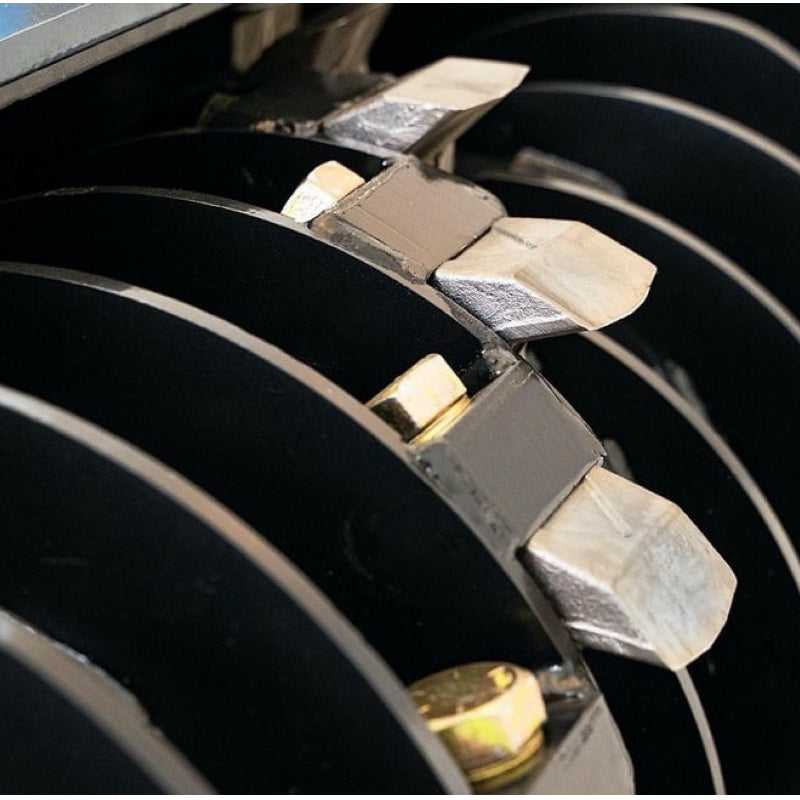

The Drum

The drum has the Promac “Chip Production Rotor” tooling system known in the industry as a “bite limiter”. This feature helps control discharge size while maintaining RPM. All holders and plates on the drum are manufactured from high strength steel for superior impact resistance and longevity.

The Teeth

The drum accepts multiple tooling options to suit any budget, performance and ground condition, including: Proprietary rotatable knives for the best mulching performance in sand or soil, double carbides for longevity in rock and economically priced beaver teeth for good performance in most conditions.

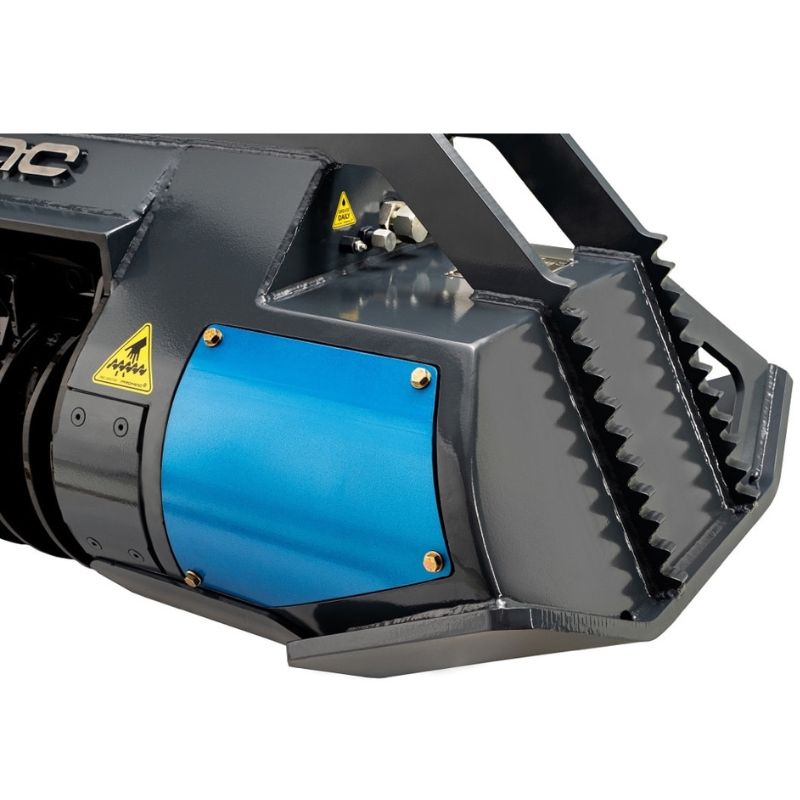

The Frame

The frame is made of fully welded high strength steel and a boxed in design, which provides better rigidity than other open-end designs. This allows the LDM Series to be light weight and maintain great machine strength and stability when operating. The frame incorporates a large ‘pusher pad’ to permit the operator to ‘push’ on the heal of the mulcher without damaging the machine.

The Add-ons

Optional Chain Bar: The optional chain bar was developed based on customer feedback and launched in early 2021. This is a simple and effective way to minimize the discharge of material out the rear of the mulcher while providing a sloped surface to guide the standing trees into the drum.

The Motor

The hydraulic motor is directly coupled to the drum via an isolation coupler. This efficient system provides shock load protection for the drive motor. The motor also includes the Promac Automatic Torque Controller (ATC) as standard.

Versatile Tooling Options

The LDM series can be fitted with tools specifically tailored to the job requirements and the desired final product. The machine is equipped with standard rotatable knives which can easily be sharpened, reversed, or changed. Double carbides are suggested to get the best results in harsh or difficult conditions. The teeth of a Beaver are an excellent alternative for most of your operational needs.

The perfect match

Not sure if the Promac LDM 30 or 50 will fit your machine? Give us a call or shoot us an email and one of our reps will gladly help you.

- Suitable for a 8-14 ton Gradall and rubber tire excavators

- Configurable to run on excavators with hydraulic flows as low as 15 GPM @ 5,000 PSI.