What Is A Case Drain On A Skid Steer

Share

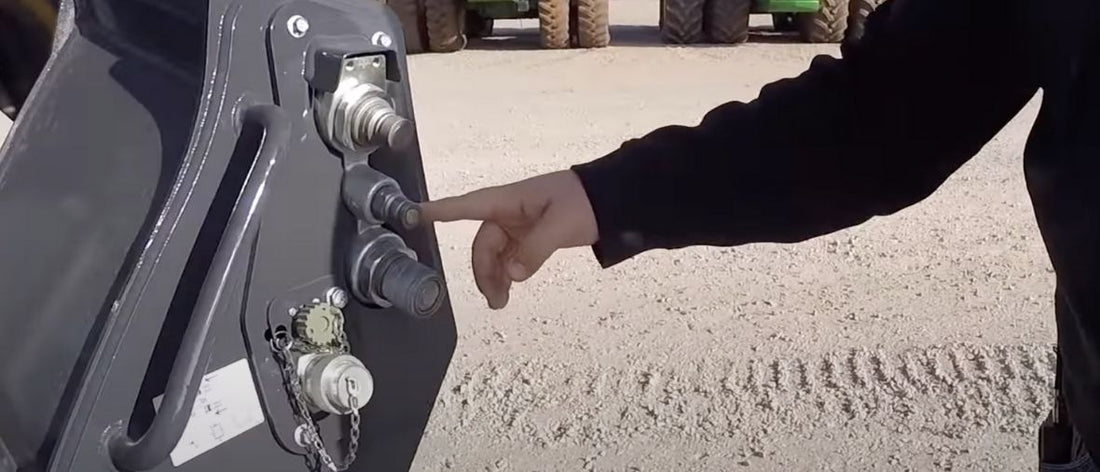

A case drain is a specific component of a hydraulic system, its objective is to extend the life of a system and reduce time spent on repairs and maintenance. An unrestricted case-drain line is essential on a piston-type hydraulic motor, whether it has axial, radial or bent-axis design. Most skid steers rely on hydraulic systems to power their front loading arms.

Sometimes referred to as a ‘third line’, a case drain drains back the oil which has leaked past the primary seal, and in doing so, prevents pressure from building up against the outer seal. This oil is then returned to the tank or reservoir.

A case drain will have an in-line case drain filter to prevent contaminants from travelling from the hydraulic motor to the tank. Operating a skid steer without a case drain line could result in a full system failure as the shaft seal will be irreparably blown out, if not installed properly your hydraulic line will not work and in worst cases become damaged beyond repair.

A good case drain makes your hydraulic system more energy efficient and lowers the pressure on the tank, good general maintenance of your hydraulic system results in longer durability for your skid steer and attachments.

Read on if you want to understand more about hydraulics, skid steers, and the function of a case drain line and it’s filter.

What Are Case Drains Made From?

A case drain is made up of multiple elements whose materials vary, it’s important to know how to remove and disassemble the case drain in order to understand its function and materials. A case drain filter is contained within an aluminum canister.

To remove the filter make sure to plug the drain lines to avoid losing hydraulic fluid or introducing contamination into the system. Simply unscrew the hex nut to access the filter element.

You may be surprised to find that case drain filters are made from a metal, sintered bronze to be specific. To the naked eye, the sintered bronze looks like one solid piece of metal but is actually thousands of bronze spheres that have been sintered together. Sintering is a heat treatment, like welding or soldering, that imparts strength and integrity to a ‘powdered’ material.

Sintering can determine a filter’s porosity which affects what goes through the filter and what doesn’t. Once sintered, the filter is now porous enough to allow hydraulic fluid to flow through it, yet remains dense enough to capture contaminants like metal and rubber debris which will eventually lead to a total system failure if left unmaintained.

When Should You Replace The Case Drain Filter?

Filters in a hydraulic system maintain fluid cleanliness at a level that maximizes component life. The appropriate cleanliness level is based on factors such as operating pressure and the internal clearances of components within a system.

If your case drain filter is blocked, then the hydraulic pressure of the motor will increase severely which will eventually lead to a myriad of mechanical and hydraulic issues and even a total system failure. Seals can be blown allowing hydraulic fluid and lubricant to leak out and also allowing contaminants to make their way into the skid steer and damage it irreparably.

If the filter in your case drain is no longer bronze in colour and looks mucky or dirty we suggest that you replace it. If your case drain is blocked then its worth dissembling the other filters and drain on the hydraulic system to ensure they have remained clean. It’s highly discouraged to attempt to clean your case drain or its filter.

Even if you had power tools or a heavy duty wire brush you will only move more trapped solids into the filter, clogging it even further. Case drain replacements are cheap when compared to replacing your whole final drive. Case drain maintenance is a key part of maintaining the life of your skid steer, and is often overlooked.

When Should A Case Drain Be Installed?

The main disadvantage of installing a filter on your hydraulics system is that back pressure created by the filter can cause total system failure caused by excessive pressure on the case drain if installed improperly

In some cases, case drains are considered optional. The case drain line is for low volume flow to the tank. In theory, by installing a high-pressure shaft seal and two check valves then internal leakage is technically drained into the return line, which is the usual function of a case line.

However, if reliability is what you are looking for then a case drain line is crucial for long term system maintenance.

It has generally been found that systems without case drains often result in failure due to shaft seal leaks. Case drain line installation can be tedious but will eradicate any problem relating to shaft seal leakage.

Oftentimes, if a vehicle doesn’t already have a case drain line fitted, the manufacturer will not necessarily outline the need for hydraulic fluid to be returned to the tank. If you want optimum reliability from your tank and hydraulics then fitting a case drain line is the way to go.

Closing Thoughts.

Case drain lines are a very specific component, its use is debated among hydraulics experts - some say you need a case drain and others suggest you don’t. Ultimately, understanding how a case drain works is fundamental to upholding your machines maintenance and making sure that your tools last for a long time.

Many system failures in hydraulics are caused by leaks from the tank. It’s important not to neglect your hydraulics system as it could put you, or your workers, at risk.

Once you know how case drain filters work and what their function is within the hydraulic system of a skid steer, then you can visit your mechanical professional and ask for their opinion on whether you need to install a case filter on your skid steer or not.

If you already have a case drain line but your tank is leaking, then you should get a mechanical professional to check if it needs to be replaced.